In 2021, a passenger ferry near Washington suffered a catastrophic engine failure. This failure was caused by a single bolt.

The resulting fire caused around $3.8m in damages, but fortunately, nobody was hurt.

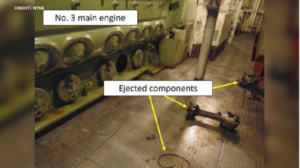

When the fastener failed, the engine ejected components that breached the crankcase and ignited hot pressurised gases; you can see the aftermath in the picture below:

This is not the first time that poor components have caused a catastrophic, costly issue, and it won’t be the last time, either.

In this blog, we’ll run through what can happen when you rely on poor quality fasteners, and what you should look for in a high-criticality fastener manufacturer in order to prevent something similar from happening to you.

What happens if you don’t use an accredited high-criticality fastener manufacturer

How confident are you with your high-criticality fasteners?

If your current manufacturer is not qualified to API20E/API20F and PED standards, you could be exposed to a substantial amount of risk. This can:

-

Pose a threat to employees and civilians

Critical failure isn’t always fire and explosions, but it very much can be.

If your industry relies on its fasteners to keep people safe, either structurally, or preventing machines from catastrophically failing, then you must ensure you’re using the highest quality products available.

The people who work for your organisation rely on you making the right decisions and choosing the best components to protect their wellbeing.

-

Cause significant financial harm

Damage to property is expensive, but if employees or members of the public are injured as a result of your fasteners failing, you could be liable to pay significant settlements, too.

Not only that, but specialised fasteners are (more often than not) used for specialist equipment. This is equipment that is incredibly expensive to repair or replace, so the fasteners you choose should always be the best of the best, from a reputable and accredited manufacturer.

-

Damage your organisational reputation

Many businesses are built on long-standing reputations. These reputations can be shattered in an instant following an event such as the one our friends in Washington suffered in the story above.

Not only is there financial damage incurred in repair costs, but the financial implications of reputational damage can often be even more severe, and can prove detrimental to attracting new business.

Take the ferries above, for example. People may now think twice before getting on – what if there’s another fire? It might not be worth the risk.

A damaged reputation is a damaged bottom line in almost any industry.

What you should look for in a fastener manufacturer

Now that we know the risks, it’s important to understand what services your manufacturer should provide, and what accreditations they should have.

Key services

There are a few key services that your manufacturer should be providing, including:

- Bespoke product manufacturing (across headed products, nuts, studs, washers and other machined components) – Your products should be created specifically for your unique needs

- A wide variety of material grades, including everything from stainless steel and carbon steels through to aircraft grades and petrochemical materials; there should be no material gaps in their offering!

- Rapid turnaround quotations – You should be able to get your quotation within 48 hours

- Emergency replacement service – During an emergency, such as a breakdown or unexpected productions stoppage, you want to know that your manufacturer is ready to support you

- Unbeatable customer support, available at all times

- Unique threaded forms – These might include, UN, ACME, BSF and more

- Plating – Copper, Nickel, Phosphate, Molykote and more, plating helps boost the versatility of your components

- Heat treatment – Various heat treatments are essential to improve the longevity of your components. This might include: case hardening, nitriding, quenching and tempering

- Testing – All products should go through rigorous testing, including highly bespoke chemical analysis, elevated tensile and proof load testing

Missing any of the above? Then it’s time to switch.

Important accreditations

Accreditations keep our industry regulated, and keep people safe.

The most important accreditations you need to look out for are:

API20E/API20F

In the oil and gas industry, “API 20E” and “API 20F” are specifications for bolts and other fasteners used in equipment and structures related to the industry. These specifications outline the requirements for the materials, dimensions, mechanical properties, testing, and other characteristics of bolts used in various applications within the oil and gas sector.

Without these certifications, you cannot be certain that your bolting is manufactured to the highest possible quality.

Pressure Equipment Directive (PED) Standards

The Pressure Equipment Directive (PED) is a set of European Union (EU) regulations that establish the essential safety requirements for pressure equipment, such as vessels, boilers, piping, and other pressure-bearing components. The directive aims to ensure a high level of safety for pressure equipment used within the EU market. The PED is also known as Directive 2014/68/EU.

Being PED certified means that a manufacturer is held to an extremely high European standard.

BS.EN.ISO 9001-2015

BS EN ISO 9001:2015 is a standard for quality management systems (QMS) developed by the International Organization for Standardization (ISO).

To become BS.EN.ISO 9001-2015 certified, an organisation needs to go through a rigorous period of assessments, meaning that if you see this qualification, you can rest assured that your manufacturer takes the quality of their products seriously.

The ISO 9001:2015 standard sets out the criteria for a quality management system that can be applied to any organisation, regardless of its size, industry, or location. The primary focus of this standard is to help organisations consistently meet customer requirements, enhance customer satisfaction, and continually improve their processes and operations.

Quality products, quality service, fully qualified – choose Wulfrun

You cannot afford to take risks with your high-quality fasteners.

That’s why you should partner with Wulfrun, leading manufacturers of high-quality special bolting and CNC machined components in the UK.

Over 35 years, we’ve worked in almost every industry imaginable, including petrochemical, aviation, subsea drilling and more; we’re even trusted by the MOD!

There is no better choice for your fastener manufacturer. Get in touch with our team today to see the Wulfrun difference for yourself.